- Home

-

Service

- Hot End

Heye Newsletter I, 2022 Part I

2022-01-11

Heye Newsletter II, 2021

海叶简报 2021年度第二期新任总裁致辞

HiPERFORM – Hot End

高性-能热端• THE GLASS PLANT OF THE FUTURE 未来的玻璃工厂

• HEYE PROCESS CONTROL 海叶工艺控制HiSHIELD – Cold End

高保障-冷端• IRIS AND HEYE COOPERATE AT CARIB GLASSWORKS 鹰锐视与海叶合作参与CARIB GLASSWORKS项目

• HEYE'S SUCCESSFUL REMOTE INSTALLATION IN THAILAND 海叶在泰国的成功完成远程安装

• MESSAGE IN A BOTTLE 瓶中咨询

DEAR CUSTOMERS, PARTNERS AND EMPLOYEES

亲爱的客户,业界合作伙伴及海叶全体员工:

allow me to start with a short introduction.

简短自我介绍。My name is Hans-Peter Müller, in October I took over the responsibility as CEO for Heye International. Since this date I have had the opportunity to meet a number of customers and most of our employees.

我的名字是汉斯-彼得.穆勒,于今年10月份正式接任海叶国际首席执行官的职责,接任初期的两个月期间,我和部分海叶客户和员工见了面,在德国总部的海叶员工给我留下了极深印象,期待着尽快能够与遍布全球的海叶客户及海叶员工见面。

I have been impressed by their knowledge, experience and dedication, making Heye International one of the leading companies for high performance machines for outstanding quality glass container production and quality inspection.

他们的知识、经验和敬业精神给我留下了深刻的印象,我相信这是海叶国际成为高质量玻璃容器生产和质量检测的高性能机器的全球领先企业之一的主要原因。The year 2021 has been a very challenging one, with a lot of uncertainty for companies, but also for their employees and families.

2021年是极具挑战性的一年,对企业、员工和家庭来说都充满了不确定性。In terms of business, 2021 came to a slow start amongst the impact of the Covid-19 pandemic, but has ultimately developed an unprecedented level of project demand. We are now proud to report a historic record booking level with a very dynamic and sustainable market demand for the years to come.

自2019年冠状病毒病(Covid-19)疫情严重影响了我们业务, 2021年初才缓慢转好,可喜的是将近年末是收到了很多新项目询价。现在可以自信的向大家报告,在未来的几年里,我们的市场需求将保持在一个非常活跃和可持续的水平。As a company, and with the strong support of our highly qualified and experienced staff, we will continue to focus on the further development of our full range of expertise. This also includes driving operational excellence and a strong focus on quality and performance, despite the very challenging situation in the entire supply chain.

尽管整个供应链面临着非常严峻的形势,海叶凭借其高素质和经验丰富的团队的大力支持,将继续专注于进一步发展其专业技术领域方的知识研发探索,同时兼顾推动卓越运营,以及对质量和绩效的高度关注。2022 will also be the year of glasstec - we are looking forward to hopefully meeting many of our customers again face to face and we can’t wait to present to you our exciting innovations, technologies and services.

期待着2022年计划的杜塞尔多夫玻璃展能如期举办,海叶将会带来诸多精彩的创新技术,届时与老朋友们相见在杜塞尔多夫。I am looking forward to meeting all of you in the near future and wish you and your families a happy, successful and exciting year 2022.

期盼与大家见面,并祝愿您和您的家人在2022年收获成功,万事如意。Stay healthy!

保重!

Sincere regards

顺祝商祺

Hans-Peter MüllerTHE GLASS PLANT OF THE FUTURE

未来的玻璃工厂Adopting the latest Industry 4.0 technologies is now crucial for the international glass container industry, says Hans Renders, Head of Product Management at Heye International. Heye offers customers a partnership on their individual path towards a smart plant, resulting in the creation of a highly automated and cost-effective glassworks.

海叶国际的产品管理主管Hans Render说:“采用最新的工业4.0技术水平,对与当今的国际玻璃容器行业是至关重要的”。海叶为客户提供的服务立场位置是合作伙伴,在与客户共同走向智能工厂的道路上并肩作战,共同创造一个高度自动化和高效率的玻璃工厂。Selection is key to defining the perfect path but it’s a challenging job to keep track of the Industry 4.0 jungle. The Glass People at Heye combine long-term process expertise and a passion for the material with advanced skills in the latest technology. Every possible solution is evaluated by the company’s process experts based on the decision criteria of financial ROI, workplace safety and influence on product quality. Heye International is your partner to select the correct technology from Industry 4.0.

通往成功需要准确选择一条正确路径,工业4.0无疑是******,但它相当具有挑战性。结合其长期积累的工艺知识和对玻璃材料的热情,海叶团队在成型领域无疑是最新的技术领先地位。为客户提供的每一种解决方案均出自公司的一套完整流程评估认证,由工艺专家根据利润率,结合作业环境安全性及产品质量标准综合评估 。海叶国际是您在工业4.0道路上的正确******合作伙伴。

Adopting the latest Industry 4.0 technologies is now crucial for the international glass container industry, says Hans Renders, Head of Product Management at Heye International. Heye offers customers a partnership on their individual path towards a smart plant, resulting in the creation of a highly automated and cost-effective glassworks.

海叶国际的产品管理主管Hans Render说:“采用最新的工业4.0技术水平,对与当今的国际玻璃容器行业是至关重要的”。海叶为客户提供的服务立场位置是合作伙伴,在与客户共同走向智能工厂的道路上并肩作战,共同创造一个高度自动化和高效率的玻璃工厂。

Selection is key to defining the perfect path but it’s a challenging job to keep track of the Industry 4.0 jungle. The Glass People at Heye combine long-term process expertise and a passion for the material with advanced skills in the latest technology. Every possible solution is evaluated by the company’s process experts based on the decision criteria of financial ROI, workplace safety and influence on product quality. Heye International is your partner to select the correct technology from Industry 4.0.

通往成功需要准确选择一条正确路径,工业4.0无疑是******,但它相当具有挑战性。结合其长期积累的工艺知识和对玻璃材料的热情,海叶团队在成型领域无疑是最新的技术领先地位。为客户提供的每一种解决方案均出自公司的一套完整流程评估认证,由工艺专家根据利润率,结合作业环境安全性及产品质量标准综合评估 。海叶国际是您在工业4.0道路上的正确******合作伙伴。

SMART USER INTERFACES

智能用户界面

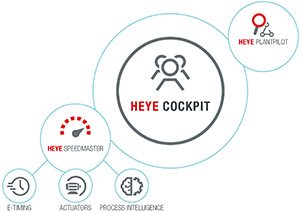

The availability of smart user interfaces for operators has become especially important. The Heye Cockpit is the central user access to the Heye SpeedMaster hot end control and process intelligence portfolio. The Heye SpeedMaster consists of three modules: E-timing, motion control (servo and pneumatic actuators) and the process intelligence solution set, combining all process control closed loops.一个智能友好的操作界面对于设备操作员来而言尤为重要。海叶的中心控制系统Cockpit结合配时,伺服驱动和智能工艺控制系统三套强大控制系统与一体,行程一条闭环工艺控制。

The approach employed is user-centric. The central collection point for all data from Heye SpeedLine is the new Communication Tower. Here, the data from all control systems of the machine are merged and managed in one central cabinet. Data integration between hot end and cold end especially helps to gain time. „With the technology behind Heye’s smart user interface our customers can respond quickly on changing production conditions and finally keep the overview, which is essential for effcient glass production,“ underlines Hans Renders.

海叶采用的数据方式是以用户为中心,从海叶SpeedLine上收集所有数据作为一座新的通信塔,数据来自行列机控制系统将在这里被合并在一个中央电控柜中进行数据分析处理。 热端和冷端之间的数据集成系统非常有效得帮助生产线节省时间(关于缺陷的出现,发现和处理时间)。”凭借海叶的智能用户界面背后的技术,我们的客户可以快速响应不断变化的生产条件,达到对于生产线的纵览把控,这一点对于一个高效玻璃生产线来说是至关重要的。”

The Communication Tower has already integrated a multi-functional remote maintenance router, which enables access via a VPN tunnel, if required.

通信塔已经集成了一个多功能的远程维护路由器,可以根据需要随时通过VPN访问。

Combined with precise mechanisms, the latest servo technology helps to achieve maximum production speed at high quality levels. High production flexibility is another result of the technology. Glass plants with short production runs and many different jobs have two advantages. First, job changes can be performed in a very short time, as important parameters will be retrieved and the major parts of the machinery will be adjusted automatically in the future. Second, the operators can produce different bottles on one IS machine, by using multi-weight assortment technology. This makes the production of samples or short job runs extremely efficient.

结合精密的机械设计和最新的伺服技术,实现高质量水平的最高生产速度。灵活性生产是该新技术的另一成果。为玻璃厂打来小批量生产和高换产品屡的两大优势。首先是快速换产,机器启动初期系统通过自动检索重要参数可以实现自动调整设置。第二,操作员可以在一台IS机器上生产多种类瓶型,实现多料重生产,使打样品和小批量产品的生产变得非常高效。

PROCESS CONTROL AND CLOSED LOOP SOLUTION SET

工艺控制系统及闭环控制解决方案

As well as being the inventor of the NNPB process, Heye has set the standard in closed loop production technology. A large set of closed loop solutions gives the customer a competitive edge. Heye offers operator assistance for gob loading, closed loops for gob shape and weight for NNPB and press-blow operation with the Heye Process Control. For heavy and premium articles produced by blow-blow operation, the Heye GobMaster satisfies demand for a closed loop solution according to gob shape and weight by visual gob measurement.

作为小口压吹工艺的开创者,海叶领先发起闭环控制,在成型技术方面树立新标准。控制方面采用多种闭环解决方案,帮助客户提供其竞争优势。海叶工艺控制系统为操作人员提供了接料位置、料形、料重及压吹工过程的闭环控制。对于压吹工艺的重量瓶及高端瓶型,海叶的GobMaster可以通过照相检测料滴,满足料形和料重的闭环解决方案。

Following the glass flow, on the blank mould side, closed loops for cooling and press duration / glass distribution are available. The Swabbing Robot eliminates one of the most important manual working steps, at the same time being the basis for precise, temperature measurement on the blank side.

接料之后,随着工艺的继续,初型侧的闭环控制体现在冷却和冲压/玻璃分布两个工艺。随后是涂油机器人,它取代了最重要的一个人工环节,同时还有初模温度的精准测量。

Closed loops on the blow side allow accurate, high speed ware handling. Dead plate cooling is controlled, creating the basis for proper bottle movement by the high speed pushers, while the closed loop for ware spacing is a second speed-relevant factor. Furthermore, both loops eliminate defects generated by an incorrect ware handling set-up. Many of these solutions are already available, while others are in the prototype phase. In some areas, operator assistance is a good first step and in other situations, full closed loop systems are already in place.

成型侧的闭环体现在高速精准的瓶罐传输环节。停滞板冷却的自动控制和次速度因数为高速运动来的玻璃瓶提供了起到好处瓶间距。这两个闭环可完全避免了由于瓶罐除设备设置错误有可能导致的热端缺陷。当其他品牌还仅仅是研发设想的时候, 海叶早已将这些闭环控制妥妥的实施到自己玻璃厂生产线上,可以说,在成型工艺的某些环节上, 海叶已经做到了完全的闭环控制。CONNECTING HOT END AND COLD END

热端与冷端的相互通讯

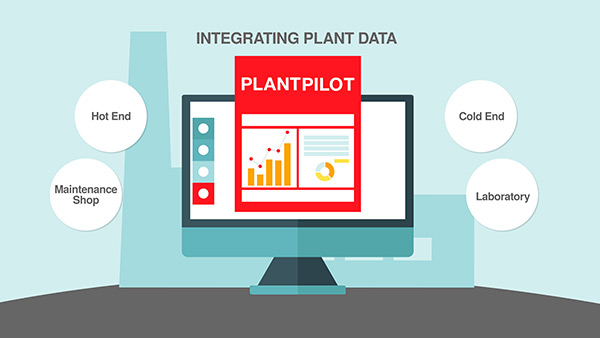

The Heye PlantPilot is a cornerstone in the field of data integration in the glass plant. By using internet-based technology, different machines or modules can be connected to manage the plant. In addition, important analysis possibilities are offered to optimise the production process. In particular, data integration between hot end and cold end helps to gain time.

海叶的工厂领航员PlantPilot在玻璃厂的信息数据领域开创了一个新的篇章。以互联网为基础,将多种机器和模块连接起来,实现数据集成。除了数据管理之外,工厂领航员还可以通过统计分析数据对生产工艺设置进行优化。特别是通过集成热端和冷端的数据,可以非常有效的节省有关缺陷的反馈处理时间。

Via the Heye Cockpit, the hot end operator has a perfect overview of the defect situation on the different cavities. By a future extension of the database to an expert system, recommendations for the correction of production defects can be given. As production companies encounter increased challenges to find skilled people, these expert systems for glass forming will become an important success factor.

通过海叶的Cockpit 中心监控,热端操作员可以对生产线的缺陷及其对应的模腔做到全面掌控。日后该系统功能还会延伸,如给予缺陷的处理措施建议。作为生产型企业,如今面临的一大难题是技术人员稀缺,可见拥有经验丰富的成型人员对于玻璃厂是多么重要。

HEYE REMOTE SERVICES

海叶远程服务

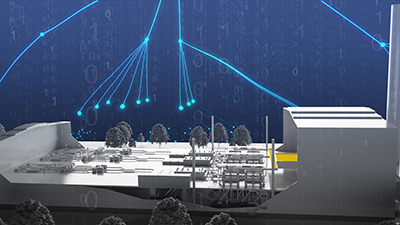

Besides supporting machine-to-machine (M2M) communication, many of the connected devices also provide an interface that allows Heye to monitor them across the Internet from any geographic location. Depending on customer settings, this remote control capability can be used to perform such tasks as virtual maintenance checks without stopping system operation. It is also used for latest software updates, failure detecting and is giving a helping hand for any imaginable scenario. Connecting machines in this way is the first step towards creating smart factories.

海叶通过互联网可以连接访问到时世界上所有运转的海叶行列机。根据客户的设置,远程控制可以多种范围形式实现, *********别可以在线更改几万公里以外的运行中的行列机动作。还可以完成远程的系统更新升级和故障诊断。这也是玻璃厂步入智能工厂的标志。

SUMMARY

总结

In summary, the Heye smart plant concept combines different innovative solutions in major areas. All of them have become possible through a set of enabling technologies, from sensors and communication networks to robots and automation. 总而言之,海叶智能工厂概念结合了主要领域的不同创新解决方案。通过一系列的技术革新,从传感器和通信网络到机器人和自动化。

The Heye Glass People are your correct partners to develop a common roadmap for the journey to a smart plant, a factory that will be able to produce high productivity containers at low cost, resource-efficiently and with a consistently high quality.

海叶国际是您前往智能工厂道路上的******合作伙伴,玻璃领域的智能工厂是一座高产能,低成本,且能源高效,质量稳定的现代化智能工厂。 - Hot End

Scan

Scan  716-722 Golden Land Building, 32 Liang Ma Qiao Road, Chaoyang District, Beijing

716-722 Golden Land Building, 32 Liang Ma Qiao Road, Chaoyang District, Beijing +86(10)6463 7797

+86(10)6463 7797 swan.si@cgeglass.com.cn

swan.si@cgeglass.com.cn