- Home

-

Service

- Hot End

The Ware Transfer

is designed to guide hot glass articles from the machine conveyor to the cross conveyor that is arranged rectangular to the machine conveyor. The device is especially designed for fast-running production machines.

Description

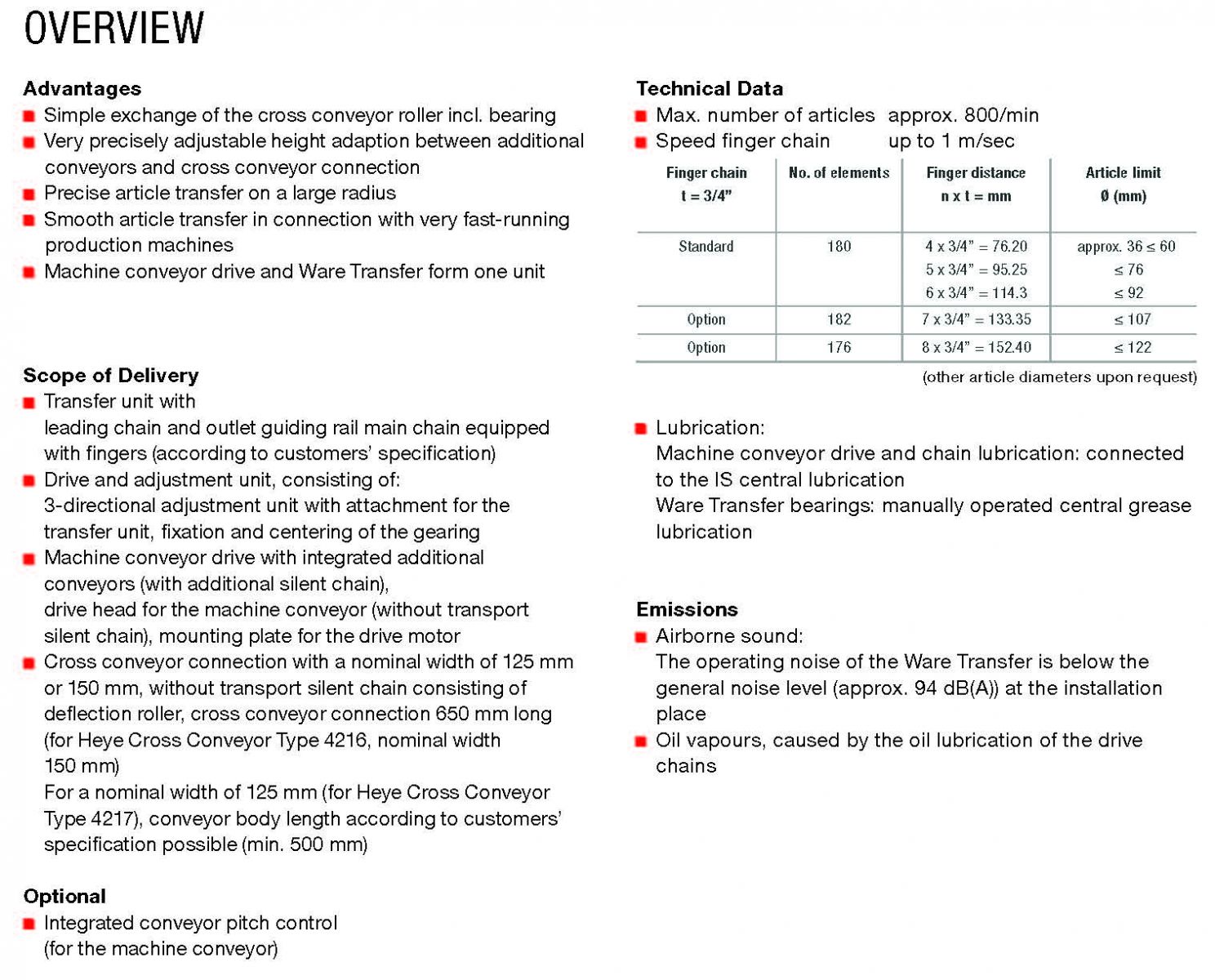

The transfer motion takes place smoothly at a large radius. Two additional short conveyors - which run parallel to the machine conveyor - support the articles during the transfer instead of a normally used transfer plate.Function

The graduated speeds between machine conveyor,

the first additional conveyor (4) and the second additional conveyor (5) determine the direction of the frictional force at the bottom of the articles to keep the articles in the “pockets” during the entire transfer. Thus, the articles reach - without contacting each other - the cross conveyor, where they are handed over to the lehr loader with defined space to each other and standing in a row.Device

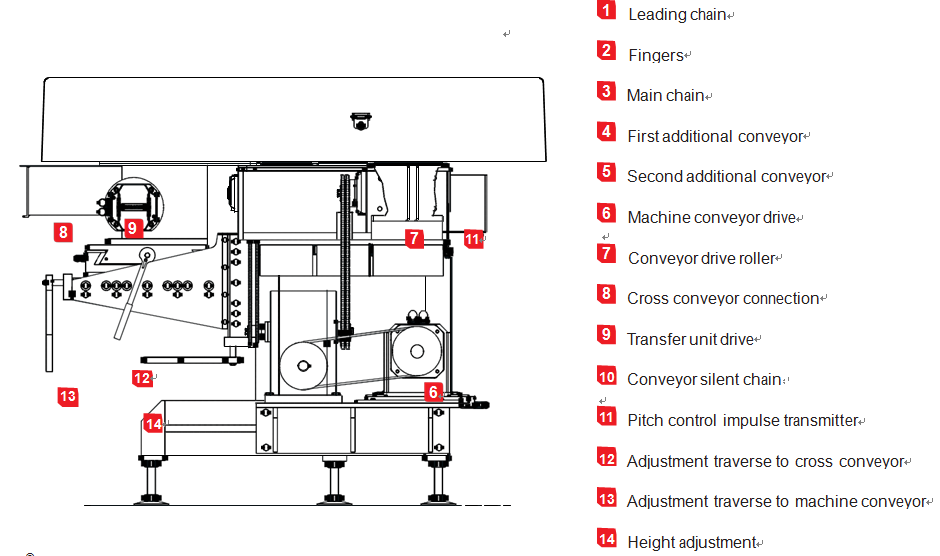

The whole device consists of the transfer unit, its drive and adjustment unit, the machine conveyor drive with the two integrated additional conveyors, the cross conveyor connection and optionally a pitch control for the machine conveyor silent chain.

The drive and adjustment unit permits to adjust the transfer unit transverse to the machine conveyor, transverse to the cross conveyor and in height by 60 mm each.Chains

Two chains effect the transfer of the articles:

The leading chain (1) for the alignment of the article flow, The main chain (3) equipped with fingers (2).The fingers of the main chain are mounted in a distance of n x ¾”. The standard chain with 180 links can transport articles up to 92 mm

For the diameter range of 92 mm up to 107 mm and 107 mm up to 122 mm, main chains with 182 and 176 links are available (options).The main chain is available with a pitch of n=4 to n=8. Depending on the pitch it has 180, 182 or 176 links.By it, glass containers with diameters between approx.36 mm to 122 mm can be transported.

Adapt The Conveyor speed

via the converter of the machine conveyor drive, the speed of the machine conveyor can be corrected according to the indication of the pitch control.Operation

Both, the speed of the machine conveyor drive (6) and the speed of the transfer unit drive (9) are set separately according to the desired article distance. Then they are commonly adapted to the number of articles.The article distance on the machine conveyor has to be larger than the finger distance of the main chain. The distance on the cross conveyor has to be smaller than the finger distance of the main chain. It can deviate by up to10 % from the finger distance. Depending on the thickness of the fingers a clear distance of at least 10 mm to 13 mm should remain between the bottles on the cross conveyor. The finger position is adjusted in phase to the arriving articles by means of the inverter of the transfer unit drive motor.

The conveyor pitch control permits to measure the pitch increase of the machine.

Conveyor silent chain (10) permanently during operation of the system.Accordingly, the motor speed can be adjusted manually at the corresponding inverter.

Options

The machine conveyor drive roller (7) is designed for a nominal width of 200 mm. A conversion to a nominal width of 150 mm is possible (option). The cross conveyor connection (8) is available for a nominal chain width of 125 and 150 mm. The length for this cross conveyor connection is 650 mm at a nominal width of 150 mm. At a nominal width of 125 mm the length can be adapted to the local space conditions provided that the minimum length is more than 480 mm. The Ware Transfer is available as left-hand and right-hand type.

As option quick change fingers can be used. They have the advantage that repair times are considerably reduced.Drive

As drive a Simotion® servo motor is used. On demand also motors of the size DIN/IEC 90 to 132 can be installed.

For further information please contact us.

- Hot End

Scan

Scan  716-722 Golden Land Building, 32 Liang Ma Qiao Road, Chaoyang District, Beijing

716-722 Golden Land Building, 32 Liang Ma Qiao Road, Chaoyang District, Beijing +86(10)6463 7797

+86(10)6463 7797 swan.si@cgeglass.com.cn

swan.si@cgeglass.com.cn