- Home

-

Service

- Hot End

For the statistical quality control of glass containers

The high quality standards on hollow glass articles request various inspections and measurements. the Heye Quality Control Software QCLab facilitates these procedures essentially and gives support to keep the quality of your articles within the given limits.

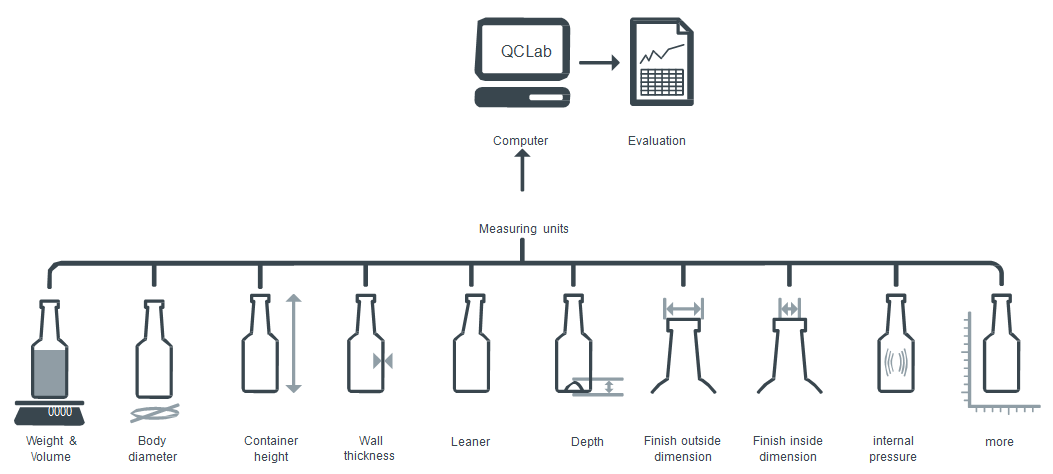

Measuring units

The following measuring units are connectable at the moment and can be supplied on request,Adaptions to additional measuring units are possible anytime after all technical details have been clarified:Container height Wall thickness Depth gauge Finish outside dimension Internal pressure Leaner Finish inner diameter Body diameter Article weight

QCLab

The software is designed to run under the operating system Windows®. The surface of windows guarantees an easy operation. The concept of operation is adapted to the operational sequences of the quality control department.The software can either be operated stand-alone or in connection with the Heye Information System. By an open measuring device interface technology data of various measuring devices can be processed. For most of the applications, a multiplexer with 8 measuring interfaces is used.

Start

First of all, the articles and their characteristic values such as for example tolerances have to be entered. The number of features which have to be checked and the belonging characteristic values can be determined optionally by the user.

All article data are stored in a database and are available anytime, e.g. after a job change.Any available database can be used.

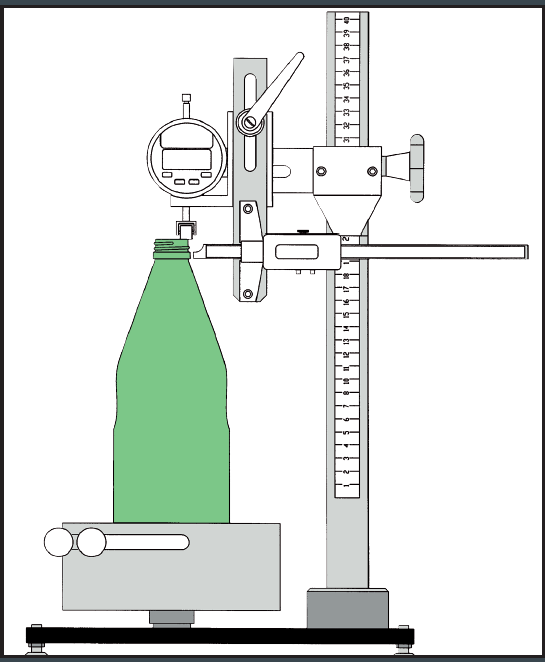

Registration of Measuring Data

The measuring values can directly be taken from the measuring units being connected or they can be entered manually. In a special polling mode the software automatically finds out the lowest and the highest measuring value. Special measuring procedures such as multiple measurement and calculation of differences are

possible. Thus, e.g. measurements of ovality, inclination and calculations of volumes can automatically be taken out.

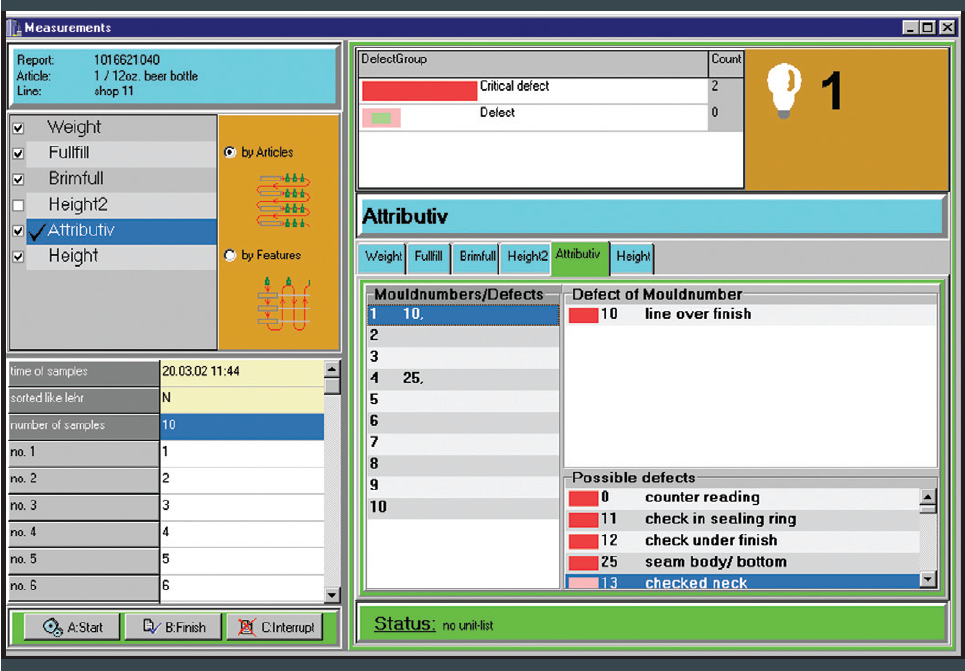

For visual quality features a special input procedure is available. Visual defects such as stones, bubbles, checks

etc. can hereby be listed and evaluated.

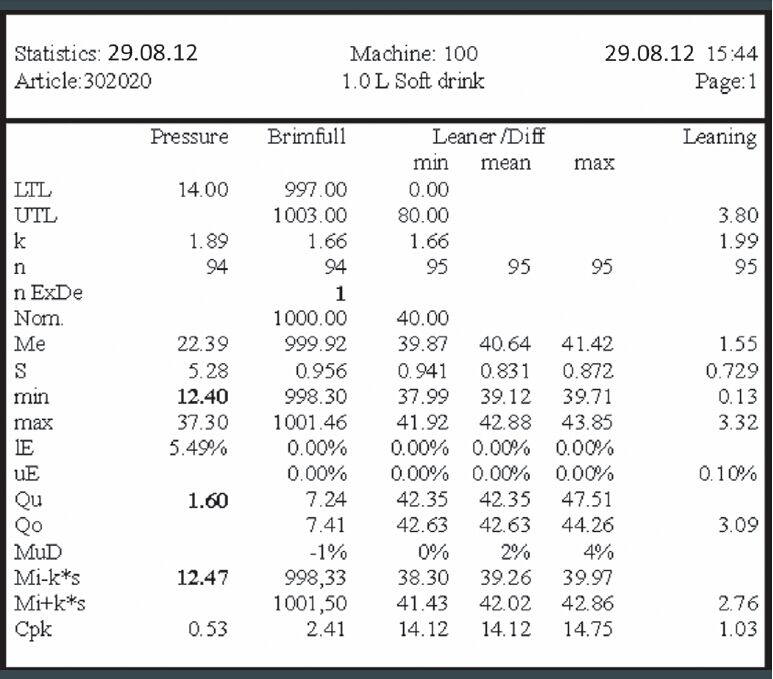

Result

After the measurements are made, protocols with single values and statistical evaluations can be printed out for each measuring series. The evaluations can also be made later over selectable periods of time.

The storage of all data is made in a database. Any available

database can be used.

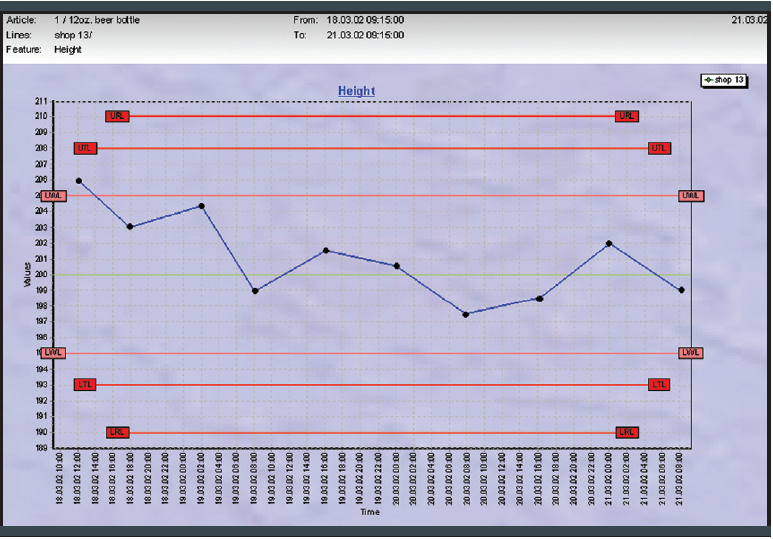

Control of the Process

Changes in the process generally cause a changing distribution of the featuring values. Control charts and distribution diagrams help to supervise and to evaluate the process. Periods, where the process is not under control can thereby be recognised, long-term changes in the process as well.

Provided that the conditions have been checked carefully, the recognition of positive changes can also be used to improve the process continuously. Time intervals, warning- and intervention limits can be set for these evaluations as desired.

Advantages

- Facilitates the quality control immensely

- Operates under Windows®

- Simple operation

- Can either be operated as stand-alone unit or in connection with the Heye Information System

- Open measuring device interface technology, i.e.data of various measuring devices can be processed (e.g. Emhart ISIS automatic dimensional gauging and weight measurement system)

- Article data are stored in a database and are available anytime, e.g. after a job change

- Various measuring units are connectable

- Registration of measuring data possible

- Statistical evaluations can be printed out for each measuring series

- The process can be controlled by charts and

- distribution diagrams

Scope of Delivery

Quality Control Software

Option

Various measuring units can be supplied on request, for instance:container height, wall thickness, depth gauge, finish outside dimension, internal pressure tester, leaner, finish inner diameter, body diameter and article weight with calculation of brimful and fillfulAlso on request: PC, multiplexer and training courses(either at Heye International or on site)

- Hot End

Scan

Scan  716-722 Golden Land Building, 32 Liang Ma Qiao Road, Chaoyang District, Beijing

716-722 Golden Land Building, 32 Liang Ma Qiao Road, Chaoyang District, Beijing +86(10)6463 7797

+86(10)6463 7797 swan.si@cgeglass.com.cn

swan.si@cgeglass.com.cn