- Home

-

Service

- Hot End

The modernization of a existing glass plant is an organisational masterstroke. the goal is a modern,high efficient production, with minimal production downtime during the realisation. Heye Internationalis synonymous with quality and innovation in planning, realisation and construction of glass plants.

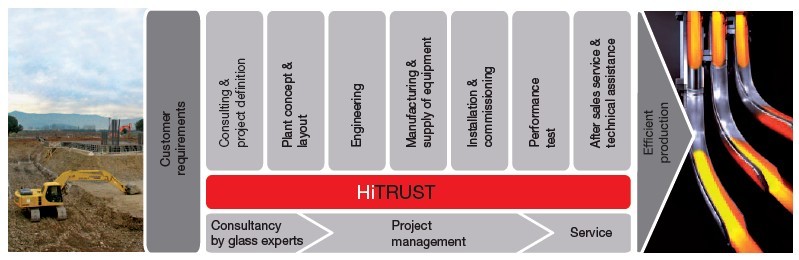

HiTRUST

Our experience of every conceivable type of container glass project, gained from projects all over the world. We call this

knowledge HiTRUST and through this initiative we can manage any and every aspect of your project.

All our competences are brought together in the HiTRUST process chain as seen below. The global in-house competence

from Heye International and our long-standing know-how, covering all project stages and processes with our large pool of

experts in each field of knowledge.

ENGINEERING COMPENTENCE

Our engineering team has the competence for all glass specific areasof a glass plant and offers with a basic design all necessary informations for more detailed budget estimation for the whole project.

The experts from Heye International are not only focused on the scope of our own equipment, we are also taking care for all the surroundings in the Hot End area.

Our Hot End detail engineering ensures that the focus of your operatorsis the manufacturing of bottles, with easy access to the equipment in the Hot End area and ergonomic arrangement of control element equipment and tools.

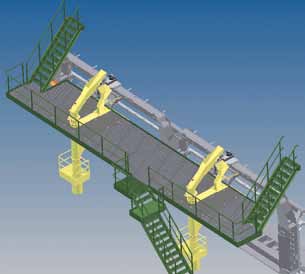

Especially our deep production background in the Hot End area offersa detail engineering package with manufacturing drawings for the surroundings like:

►Complete Hot End layout

►Glass collecting funnel and chutes

►Intermediate platform with stairs

►Load distribution plate with support steel structure

and oil collecting device►Compressed air and vacuum connections with pipe routing in the Hot End area

►Pipe routing for central lubrication

►Water connections with pipe routing in the Hot End area

►Cooling air supply with ducting and layout of the blower positions

►Layout of machine control room with cable routing

►Risk analysis (e.g. noise analysis, fire fighting,

safety arrangements)A very important part is the definition and description of the interfacesin the Hot End area. A clear definition of the interfaces with Hot End layout, drawings with pipe and cable routing and manufacturing drawings for the surroundings in the Hot End area, like intermediate platform, gob funnel etc. the time for the procurement and installation will be reduced and the works well organized.

Another important detail is the cable routing to protect cables against hot glass and cullet. Heye International is taking care for the water distribution at the IS-Machine to make sure that the hot glass can be cooled every time. Also important is the protection of the equipment and control systems against water to avoid malfunctions.

We are using our know-how and our experience to design user-friendlyworking conditions for the operators, so they can set their focus in quality and efficient production of glass containers.The Heye International Hot End detail engineering is proven in a plenty of glass plants worldwide.

INSTALLATION AND COMMISSIONING

The Heye International service department is prepared to take care for the installation of the Heye International equipment and the correspondingsurroundings. This can be done with local contractors underthe supervision of Heye International experts or as our approved turn-keyinstallationThe experienced production specialists from Heye International will train the machine operators in their daily work, maintenance, troubleshooting and will start the production.

If required, Heye International is able to provide a performance test for equipment or a defined production area.

Depending on the scope of the project Heye International will provide a site manager who will support the customer in the coordination of the works to finalize the project in time and quality.

- Hot End

Scan

Scan  716-722 Golden Land Building, 32 Liang Ma Qiao Road, Chaoyang District, Beijing

716-722 Golden Land Building, 32 Liang Ma Qiao Road, Chaoyang District, Beijing +86(10)6463 7797

+86(10)6463 7797 swan.si@cgeglass.com.cn

swan.si@cgeglass.com.cn