- 首页

-

专业服务

- 热端

海叶简报 2022年度第一期 第二部分

2022-01-13Heye Newsletter I, 2022 Part II

海叶简报 2022年度第一期 第二部分

新任总裁致辞

HiPERFORM – Hot End

高性-能热端• THE GLASS PLANT OF THE FUTURE 未来的玻璃工厂

• HEYE PROCESS CONTROL 海叶工艺控制HiSHIELD – Cold End

高保障-冷端• IRIS AND HEYE COOPERATE AT CARIB GLASSWORKS 鹰锐视与海叶合作参与CARIB GLASSWORKS项目

• HEYE'S SUCCESSFUL REMOTE INSTALLATION IN THAILAND 海叶在泰国的成功完成远程安装

• MESSAGE IN A BOTTLE 瓶中咨询HEYE PROCESS CONTROL: AN INCOMPARABLE SUCCESS STORY

海叶工艺控制:成功案例

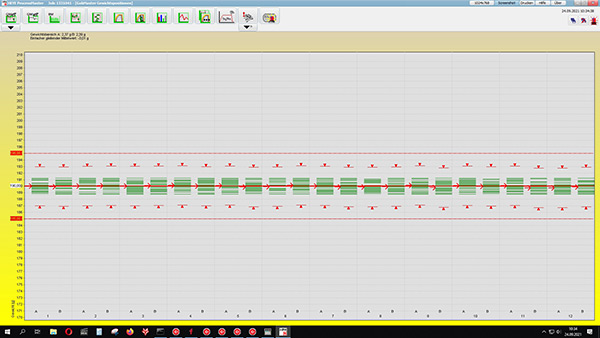

As it reaches over 1000 process controls delivered to customers, Heye is the leading partner for process optimisation, regulation and digitalisation of the NNPB process. According to Hans Renders, Head of Product Management at Heye International, the Heye Process Control 4.0 (HPC) was the crucial milestone to initiate Industry 4.0 within the glass industry.

目前全球玻璃厂使用海叶的工艺控制系统数量已超过1000条生产线。海叶在小口压吹工艺的数字化及工艺优化方面,已成为玻璃工厂具备工业4.0水平的标志。The Heye Process Control 4.0 is a closed-loop-solution for the press process of all plunger mechanisms within an IS-machine. Simultaneously, it keeps the gob weight stable. Its computer interface displays a number of forming events on selectable charts and allows users to improve parameter setting by comparing data.

海叶的工艺控制系统4.0是一全闭合方案,控制一台行列机上所有芯子机构的冲压过程,从而实现料重稳定。电脑操作界面根据需求选取相应的曲线,横向比较以便改行列机的参数设置。

Early detection of malfunctions increases production efficiency. The integrated plunger cylinders guarantee precise and consistent parison parameters for press-blow and NNPB production.

提早发现错误设置即使采取修改措施,很大程度上提高了生产效率。内置的芯子气缸确保压吹和小口压吹生产的精确模腔参数设定。

By delivering the 1000th HPC, Heye comprehensively demonstrated that it has recognised and fulfilled the approach required by the market for stable and sustainable process data management in the past decades. The Heye Process Control is the essential closed-loop- system for every glass manufacturer in order to meet the high quality requirements of NNPB production.

随着海叶为客户交付第1000套工艺控制系统HPC,这证明再过去的几十年中, 海叶早已认识到市场对于工艺过程的数据管理的需求。

Changes in customers’ process requirements have driven Heye International engineers to modify the Heye Process Control (HPC) from solely a plunger sensor to a holistic solution. The data acquisition from different sensors and the regulation of process parameters are now realised in the Heye ProcessMaster in which the Heye Process Control becomes a subsystem.

随着客户对工艺的需求不断增加难度,海叶国际的工程师们对海叶工艺控制系统(HPC)进行了改进,从单一的芯子气缸传感器转变为工艺解决方案。如今HPC增加一个全新的次级模块 Heye ProcessMaster (HPM),采集所有芯子气缸传感器的数据结合工艺控制参数进行自动调节。The Heye ProcessMaster (HPM) is a modular central software solution which is used as a basis for most sensor solutions in Hot End production. HPM makes it now possible to implement single sensors as well as complex sensor systems.

HPM 是一种模块化的中控软件解决方案, 用于处理热端工艺部分的大多数传感器数据。HPM实现了单个传感器和多个传感器的复杂集成。These sensors are for example:

这些传感器包括如下:the Heye GobMaster for weight control of BB-process and additional information like gob-shape, temperature and dimensions

海叶GobMaster用于吹吹工艺的料重控制以及料形,料温和料滴尺寸等信息。the Heye BlankMaster, which monitors different mould part temperatures and gob loading at the blank side

海叶BlankMaster用于检测模具每个部件的温度和初型侧的接料位置。stand-alone gob temperature sensor

独立式料滴温度传感器。

All collected sensor and machine data can be used inside the production process to regulate process parameters like gob weight, press duration or mould part temperatures.

收集到的传感器信号和行列机的数据将被用于生产工艺上的参数调节, 例如料重,冲压时间和模具组件温度。All collected process data is stored in the HPM for seven days.

HPM 储存数据的时间长达7天。The collected data can also be extracted via Heye SmartLink to be used by a third-party get a long-term history of all relevant machine and process data. This helps to generate a better understanding of the process and the machine behaviour and consequently to implement optimisations on process and machine.

收集到的数据也可以通过海叶SmartLink提取供第三方MES(制造执行系统)使用,以获得所有相关机器和工艺数据的长期历史。这有助于更好地理解整个工艺和机器的自身特性,从而优化工艺流程。

In addition to all these hardware optimisations, Heye is always in contact with its customers to set up user interfaces for a friendlier and more intuitive operation. Hence, the HPM gets a reworked user interface on each operating system update to let the operator feel more comfortable and familiar when handling the system.

除了上述的硬件优化之外,海叶始终与客户保持联系并建立更友好、更直观的用户界面。因此,HPM在每个操作系统更新是都会重新设计用户界面,让操作人员在操作系统时感到更舒适和熟悉。

HEYE'S SUCCESSFUL REMOTE INSTALLATION IN THAILAND

海叶在泰国成功完成远程安装

When machinery and equipment is to be installed, our Heye experts travel around the world – usually. But what is still „usual“ and „normal“ these days? We are all longing to return to the good old times when terms such as „social distancing“, „home schooling“ or „travel restrictions“ did not determine our lifes. And yes, we will get back to these glorious times one day. But this requires patience and stamina – and new ideas and steps in the meantime.

通常情况下,在准备安装机械和设备时,海叶的专员们会前往全球的客户所在地执行项目。但现如今的“通常”和“正常”又是什么呢?我们都渴望回到过去的美好时光,那时我们的生活中没有充斥着诸如“社交距离”、“居家教育”或“出行限制”。毋庸置疑,总有一天我们的美好时光必将会恢复。但这需要耐心和毅力,同样也需要新想法和步骤。So we are very proud that again, Heye experts - in cooperation with a great customer’s team on site - successfully installed and commissioned an IS-machine via REMOTE ACCESS.

通过海叶专员与现场优秀客户团队的合作,借助远程的方式成功完成了一台行列机的安装和调试,对此我们感到非常自豪。

The 8 Sect. 5inch DG IS-machine (overhauled) runs NNPB operation and produces lightweight juice bottles.

8组 5”双滴机(大修),小口压吹生产轻量果汁瓶。

This project was accomplished remotely with Heye experts‘ knowledge in Germany and powerful performance of the L. Lighting Glass team in Thailand. Our thanks also go to our local partner in Bangkok who tremendeously supported the team on-site.

在海叶专员从德国提供的远程技术支持以及泰国L. Lighting Glass 团队的出色工作下,此项目圆满完成。此外,我们还要感谢在曼谷的当地合作伙伴,他们在现场为团队提供了极大的支持。IRIS AND HEYE COOPERATE AT CARIB GLASSWORKS

鹰锐视与海叶携手打造CARIB/加勒比玻璃厂项目

Container glass manufacturer Carib Glassworks in Trinidad benefited from Iris and Heye's cooperation.

位于特立尼达拉的Carib/加勒比玻璃厂受益于海叶与IRIS的合作Camera and check inspection solutions specialists, Iris Inspection machines and Heye International have gathered in a synergy.

照相与裂纹检测方案专家: IRIS检验机与海叶国际强强联合。

The cold end alliance, named WENSPECT, has proved working together as one, its ability to overcome challenges at Carib Glassworks, the only glass container plant in the Caribbean.

名为WENSPECT的冷端联盟,一体化发展,克服了加勒比海区域唯一一家瓶罐玻璃厂Carib项目的挑战。The factory produces standard and custom-made containers in flint, green and amber for customers in the soft drinks, beer, food, alcohol and juice sectors.

该工厂生产白色,绿色和茶色的标准瓶和客户定制瓶,用于软饮,啤酒,食品,烈酒和果汁的包装。

In 2016, the glassworks doubled production capacity to 70,000 tons/year via the commissioning of a second melting furnace and three production lines.

2016年,加勒比玻璃厂新建一座窑炉配备3条生产线,将其年产能翻倍只7万吨/年。

Carib Glassworks started working with Heye International almost 50 years ago equipping one furnace with Heye IS machines and Heye carousel machines for the cold end.

加勒比玻璃厂与海叶有着长达50年的合作历史,50年前的第一座窑炉即配备了海叶的行列机和裂纹检验机。In 2015, as they were facing new quality challenges, Iris Inspection machines delivered non-contact inspection solutions for five production lines.

2015年,正当客户面临最新的质量挑战之时IRIS检验机交付了5条生产线的无接触式检测设备。

Sharing the same passion for collaboration, Iris and Heye, now joined in WENSPECT alliance, have supported the glassmaker's business expansion initiatives, in a close working relationship.

IRIS与海叶,秉持共同的合作激情,携手建立了WENSPECT联盟,以紧密的合作关系,为玻璃制造客户的发展壮大提供有力支持。

"This is the kind of cooperative dynamic that we establish with our customer. So we have been delighted to find this level of support and service with IRIS and Heye." says Ms Tahira Khan, Project Manager at Carib Glassworks.

“这就是我们与客户建立的合作关系,我们很高兴能够从IRIS和海叶获得高水平的支持和服务”加勒比玻璃厂的项目经理Tahira Khan女士如是说。

Having encountered wire edge and overpress defects last year, the glassmaker relied on IRIS solution, with the installation of the Wire Edge module on two production lines. Carib Glassworks has been impressed with the results achieved, so much so that at the beginning of 2020, all the impacted lines were equipped with the dedicated wire edge module.

自从去年遇到了飞边和冒口缺陷后,玻璃制造商们依赖于IRIS的解决方案。

在两条生产线上安装了飞边检测工位之后,取得的成效令加勒比玻璃印象深刻,因此与2020年初,即将全部生产线都安装了指定的飞边检测工位。Located in Port of Spain, Trinidad, Carib Glassworks has a history dating back to 1948.

加勒比玻璃厂位于西班牙湾的特立尼达岛,其历史可追溯到1948年。

The glassworks is a member of the ANSA McAL Group of Companies, its founding fathers having laid the platform for a highly automated manufacturing facility, employing some of the best regional technical professionals.

这家玻璃工厂是ANSA McAL集团的成员之一,其创始人为高度自动化的制造设施奠定了平台,雇佣了当地最好的专业技术人员。MESSAGE IN A BOTTLE 瓶中资讯

Last week we received the following email from the Isle of Anglesey:

Hello from the Isle of Anglesey in North Wales, I hope you can help. After last night's very stormy weather I found a glass float on the beach. I've identified the stamp and it was made by Heye Glass Manufacturers. I'm trying to find out how old it might be. Would you be able to find out when the company stopped producing glass floats please?

Thank you so much for your help ????上个星期我们收到一封来自安格尔西岛的邮件:

你好,这里是北威尔士安格尔西岛的问候,希望贵司能帮上忙。昨晚我们这里暴风雨过后,我在海滩上发现了一个玻璃浮球。能够清晰看到这个玻璃球上的刻花,我知道这是海叶玻璃厂制造的玻璃球。请问能否查到海叶玻璃厂最后一批玻璃球是那也年生产的?这样我就可以知道这个玻璃球的年纪了。

非常感谢你的帮助。

The ball shown is a floating ball that was used for fishing. They were used to keep fishing nets on the surface by the buoyancy of the air trapped in them. The floating balls are actually blown balls, originally blown free and later blown into shape. They were locked in a string net attached to the edge of the fishing net. Heye Glass manufactured these spheres from 1910 to the 1950s.

照片中的玻璃球是一个用来捕鱼的浮球。利用空气的浮力将渔网固定在水面上。漂浮球实际是吹吹出来的,最初随意吹,后来渐渐发展有个固定的外形。它们被锁在渔网边缘的细网里。海叶玻璃公司曾于1910年到20世纪50年代期间生产过这些玻璃球。

It's a pity that the glass ball that's washed up can't speak. It could certainly have told a lot about her travels on the oceans of this world.

被冲上岸的玻璃球如果会说话,一定能告诉我们很多关于她在这个世界上的海洋旅行的事情。 - 热端

扫一扫 关注公众号

扫一扫 关注公众号  北京市朝阳区亮马桥路32号高斓大厦716-722

北京市朝阳区亮马桥路32号高斓大厦716-722 +86(10)6463 7797

+86(10)6463 7797 swan.si@cgeglass.com.cn

swan.si@cgeglass.com.cn